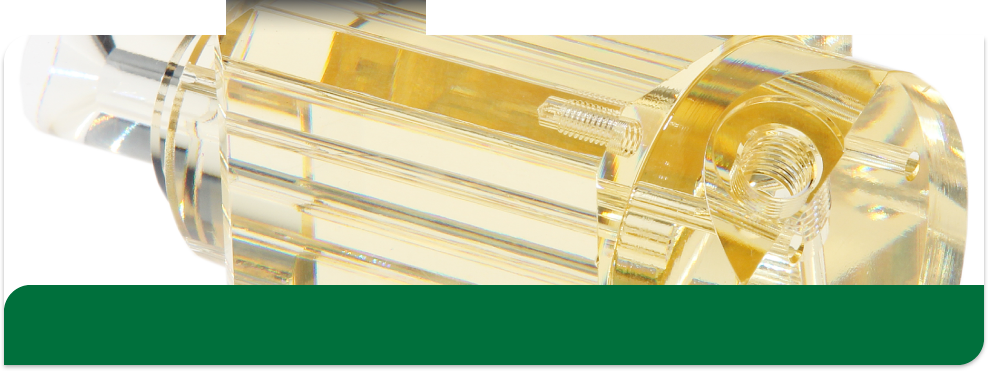

Though 3D milling is not a new concept, it has become far more precise than it has ever been before, with the introduction of computerized software. Unlike its younger 3D printing sibling, this method uses subtraction and is often referred to as CNC milling. With this technology, it becomes possible to use a single piece of material, such as a block of steel to form a component that will ultimately become part of a larger machine. This method can be used for the manufacture of machine parts, automobile parts, infrastructure pieces, aircraft, and a plethora of other applications.

A More Precise Approach

CNC Milling or Routing has always been a very precise science, but as of late, with the introduction of high-end computer design software, it has become far more precise than it ever was. Machine parts can now be manufactured down to the smallest specification, and the software can even determine what order the parts will be made in. The amount of control over 3D milling techniques is staggering when you think about it.

There are two major types of 3D Milling which include:

Face Milling: Cutting action is performed at the edge corners of the cutter. This is used to cut flat surfaces into their final shape or create flat bottomed cavities in the material.

Peripheral Milling: This is the most complicated method in which the milled surface will end up taking on the shape of the cutter. Essentially, the blades will scoop material from the work piece, making it excellent for cutting deep slots, gear teeth, and more.

The Hand that Machines

While the software changes things to a great extent, it would be absolutely nothing if it did not have a skilled, highly trained hand guiding it. The employees behind their family owned business have the knowledge and the experience required to make this not only a rousing success but a force to be reckoned with in the industry. As you probably know, the creation of these parts is a skilled craft just because the function of an entire machine can depend upon the proper creation of these parts. When you’re in the market for a mill job, remember that they can create parts of any type whether it is a prototype or a full product line. Don’t trust your milling to less than the best.